Few household inconveniences are as alarming as an electric kettle that boils endlessly, its switch stubbornly refusing to flip off. This not only wastes energy but, more critically, poses a significant safety hazard, from potential fire risks to severe burns. If you’ve encountered this troubling issue with your electric kettle, rest assured you’re not alone. This guide will delve into the common culprits behind a malfunctioning auto shut-off, equip you with safe and effective troubleshooting steps, and help you determine when a simple fix is possible versus when it’s time to invest in a new appliance. Prioritizing safety, we’ll navigate the intricacies of kettle mechanics to keep your kitchen secure and your hot water flowing as intended.

Understanding Your Electric Kettle’s Auto Shut-Off Mechanism

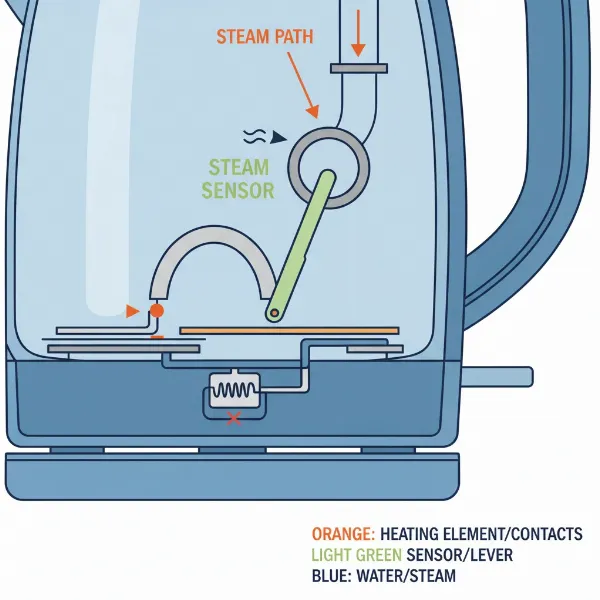

At the heart of every modern electric kettle is a sophisticated safety feature: the automatic shut-off mechanism. This ingenious design prevents over-boiling, dry boiling, and excessive energy consumption. Typically, this system relies on a bimetallic strip or a steam sensor located near the kettle’s lid or handle. As water boils, steam rises and is directed towards this sensor. When a sufficient amount of steam reaches the bimetallic strip, the heat causes it to flex, tripping a lever that disengages the power supply to the heating element, thereby turning the kettle off. This seemingly simple process is critical for preventing accidents and ensuring the kettle operates safely within its design parameters.

Diagram of an electric kettle's auto shut-off mechanism showing bimetallic strip and steam sensor

Diagram of an electric kettle's auto shut-off mechanism showing bimetallic strip and steam sensor

Immediate Safety Precautions When Your Kettle Won’t Turn Off

Discovering your electric kettle continuously boiling can be startling. Your very first action must be to unplug the kettle from the power outlet immediately. Do not attempt to move the kettle, open its lid, or pour water from it while it is still connected to power and boiling. A continuously boiling kettle can lead to several dangerous scenarios: it can boil dry, potentially damaging the heating element and creating a fire hazard, or erupt with scalding steam and water, causing severe burns. Until the issue is fully diagnosed and safely resolved, under no circumstances should you continue to use the kettle. Your safety and the safety of your home are paramount.

Common Reasons Your Electric Kettle Switch Stays On

Several factors can cause an electric kettle’s auto shut-off switch to malfunction, leading it to boil indefinitely. Understanding these common culprits is the first step toward effective troubleshooting.

- Limescale Buildup: This is arguably the most frequent cause. Hard water leaves mineral deposits (limescale) that can accumulate around the heating element, the internal steam vents, and even on the bimetallic strip itself. This buildup can physically block steam from reaching the sensor, insulate the sensor from the steam’s heat, or impede the mechanical movement of the switch.

- Blocked Steam Vent: The small vent, usually located in the lid or near the spout, is crucial for directing steam to the auto shut-off sensor. If this vent becomes clogged with limescale or food particles, steam cannot properly signal the sensor, preventing the kettle from turning off.

- Faulty Thermostat or Bimetallic Strip: Over time, the bimetallic strip—the heat-sensitive component responsible for tripping the switch—can become worn, bent, or simply fail. This is an internal component failure and typically requires professional repair or replacement of the kettle.

- Mechanical Switch Malfunction: Less common, but sometimes the physical on/off switch mechanism itself can become stiff, jammed, or worn out. This might prevent it from returning to the “off” position even if the internal safety mechanism has been triggered.

- Electrical Faults: While rare for just the switch, internal wiring issues or a short circuit within the kettle’s base or body could potentially interfere with the shut-off function. Any electrical fault poses a serious safety risk and should only be handled by a qualified technician.

> “Always remember that an electric kettle combines water and electricity. If you suspect an electrical fault, or if you’re not confident in your DIY skills, replacing the kettle is often the safest and most cost-effective solution.” – Dr. Eleanor Vance, Appliance Safety Engineer

Troubleshooting Steps: Diagnosing the Problem Safely

Before attempting any fixes, ensure your kettle is unplugged and has completely cooled down. Start by carefully inspecting the kettle for any obvious issues.

- Visual Inspection for Limescale: Open the lid and look inside the kettle. Is there a white, chalky buildup on the heating element or the kettle’s interior walls? Pay close attention to any areas near the lid’s hinge or spout where steam vents might be. Significant limescale is a strong indicator of the problem.

- Check for Blocked Steam Vents: Carefully examine the small openings or channels, usually on the underside of the lid or near the top of the handle, designed to release steam. Use a flashlight if needed. Are they clear, or do they appear clogged with mineral deposits or debris?

- Inspect the Kettle’s Lid: Ensure the lid closes securely and forms a tight seal. A loose-fitting lid might allow too much steam to escape, preventing enough steam from reaching the auto shut-off sensor.

- Examine the On/Off Switch: With the kettle unplugged, gently operate the physical on/off switch. Does it move freely and click into position, or does it feel stiff, stuck, or loose? Look for any visible obstructions around the switch mechanism.

Step-by-Step Fixes for a Malfunctioning Kettle Switch

Once you’ve diagnosed the potential cause, you can attempt these safe, DIY fixes.

Descaling Your Electric Kettle

Descaling is often the most effective and safest DIY solution for a kettle that won’t turn off due to limescale.

- Vinegar Method:

- Fill the kettle halfway with equal parts white vinegar and water.

- If your kettle can safely boil (i.e., it eventually turns off, just slowly, or you can manually unplug it after it boils), boil the mixture. If it boils endlessly, simply let the mixture sit for 30 minutes to an hour without boiling.

- Allow the solution to sit for at least 30 minutes, or longer for heavy buildup. You might see the limescale dissolving.

- Pour out the solution and rinse the kettle thoroughly several times with fresh water to remove any vinegar residue and smell.

- Fill with fresh water, boil, and discard this water to ensure no taste remains.

- Citric Acid Method:

- Dissolve 1-2 tablespoons of citric acid powder (available in most supermarkets) in a liter of water.

- Pour the solution into your kettle.

- Boil the solution (if safe) or let it sit for 30-60 minutes.

- Rinse thoroughly and perform a final boil with fresh water.

Person descaling an electric kettle with vinegar and water to fix a faulty switch

Person descaling an electric kettle with vinegar and water to fix a faulty switch

Clearing Blocked Steam Vents

After descaling, ensure the steam vents are completely clear.

- Use a soft brush (like an old toothbrush) or a damp cloth to gently clean around any small openings or grates near the lid or spout.

- For stubborn blockages in tiny crevices, a toothpick or a small, non-metallic probe can carefully dislodge mineral deposits. Be gentle to avoid damaging plastic components.

Addressing Mechanical Switch Issues (with caution)

If you’ve identified a stiff or jammed physical switch and no internal electrical fault is suspected:

- Ensure the kettle is unplugged.

- Gently try to work the switch back and forth a few times. Sometimes, a minor obstruction or stiffness can be loosened.

- Inspect for any visible debris or plastic fragments that might be physically impeding the switch’s movement and carefully remove them. Do not force the switch.

When to Seek Professional Help or Replace

If descaling and cleaning steam vents do not resolve the issue, or if you suspect an internal electrical or thermostat fault, it is strongly advised not to attempt further DIY repairs. Electric kettles are generally not designed for user-serviceable internal components.

- Electrical Faults: Any sign of burning smells, flickering lights, or sparking requires immediate replacement.

- Persistent Issue: If the kettle continues to boil endlessly after thorough cleaning, the bimetallic strip or thermostat is likely faulty.

- Cost-Effectiveness: Often, the cost of having a professional appliance technician repair an electric kettle outweighs the cost of purchasing a new, safe, and efficient model. Prioritize your safety and consider a replacement.

Preventive Maintenance to Ensure Your Kettle’s Longevity and Safety

Regular maintenance can significantly extend the life of your electric kettle and prevent frustrating switch malfunctions.

- Regular Descaling: Depending on your water hardness, descale your kettle every 1-3 months. This is the single most effective way to prevent limescale buildup from affecting the auto shut-off mechanism.

- Avoid Overfilling: Filling the kettle beyond the “max” line can cause water to boil over and potentially interfere with the steam path to the sensor, or even seep into electrical components.

- Ensure Proper Lid Closure: Always make sure the kettle lid is securely closed before boiling. A loose lid allows steam to escape inefficiently, preventing it from reaching the auto shut-off sensor.

- Keep Steam Vents Clear: Periodically check the steam vents for any visible obstructions and clean them as part of your routine maintenance.

- Empty After Use: While not directly related to the switch, emptying the kettle after use can help reduce mineral deposit formation.

Troubleshooting Guide: Kettle Switch Won’t Turn Off

This table provides a quick reference for common symptoms and their solutions regarding a non-functional kettle switch.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Kettle boils endlessly | Heavy limescale buildup, blocked steam vent | Thoroughly descale kettle, clear steam vents |

| Switch feels stiff/jammed | Mechanical obstruction around the switch | Inspect for debris, gently manipulate the switch |

| No change after cleaning | Faulty bimetallic strip/thermostat, electrical | Replace kettle or seek professional repair |

| Kettle turns off too early | Minor limescale affecting sensor sensitivity | Descale kettle more frequently |

| Kettle smells like burning | Electrical fault, overheating | Unplug immediately, discontinue use, replace |

Common Kettle Switch Problems and Quick Solutions

Beyond a complete failure to turn off, other switch-related issues can arise, often pointing to similar underlying causes. If your kettle switches off too early, even before reaching a full boil, it could be due to minor limescale deposits making the sensor overly sensitive, or simply a slightly damp sensor from condensation. Regular descaling can often fix this. If the kettle takes an unusually long time to boil, it might indicate an inefficient heating element, though a compromised auto shut-off mechanism could also contribute by not sensing the temperature correctly. Finally, steam leaking excessively from areas other than the designated vents can prevent enough steam from reaching the sensor, causing it to continue boiling. Ensure all seals are intact and the lid is properly seated.

Investing in a New Electric Kettle: What to Look For

If your troubleshooting efforts prove unsuccessful, or if safety concerns persist, replacing your electric kettle is the most prudent choice. When buying a new one, prioritize models with reliable safety features. Look for kettles that explicitly mention robust auto shut-off and boil-dry protection. Consider models from reputable brands known for their quality and safety standards. Features like precise temperature control, durable materials like stainless steel or borosilicate glass, and an easily accessible wide opening for cleaning can also enhance your user experience and make future maintenance simpler, potentially extending the life of the auto shut-off mechanism.

Conclusion

A malfunctioning electric kettle switch that refuses to turn off is more than an annoyance—it’s a critical safety concern that demands immediate attention. Fortunately, many instances are resolvable with simple, safe DIY fixes like thorough descaling and clearing obstructed steam vents. By understanding how your electric kettle’s auto shut-off mechanism works and taking proactive steps for maintenance, you can significantly reduce the risk of such failures. However, always prioritize your safety. If the problem persists after basic troubleshooting, or if you suspect a deeper electrical issue, it is always safer to replace the appliance than to risk injury or damage. Keep your kitchen safe and your tea time enjoyable. What steps do you typically take to maintain your electric kettle?

Frequently Asked Questions

Why does my electric kettle keep boiling?

Your electric kettle likely keeps boiling due to limescale buildup blocking the steam vent or affecting the internal thermostat (bimetallic strip). This prevents the auto shut-off mechanism from sensing steam or heat correctly, causing it to boil continuously. Descaling and cleaning the steam vents are often effective solutions.

Is it safe to use an electric kettle if the auto shut-off isn’t working?

No, it is absolutely not safe to use an electric kettle if the auto shut-off isn’t working. A continuously boiling kettle poses serious risks, including boiling dry, which can damage the appliance and cause a fire, or erupting with scalding steam and water, leading to severe burns. Unplug it immediately and do not use it until the issue is resolved.

How often should I descale my electric kettle to prevent switch issues?

The frequency of descaling depends on the hardness of your local water. For areas with very hard water, descaling every 1-2 months is recommended. In areas with moderately hard water, every 3-4 months should suffice. Regular descaling is crucial for maintaining the efficiency and safety of your kettle’s auto shut-off.

Can a faulty electric kettle switch be repaired by myself?

Basic issues like limescale buildup or blocked steam vents can often be safely remedied by yourself through descaling and cleaning. However, if the problem lies with an internal component like the bimetallic strip, thermostat, or an electrical fault, self-repair is generally not recommended due to safety risks. In such cases, professional repair or replacement is advisable.

What is a bimetallic strip in an electric kettle?

A bimetallic strip is a crucial component in many electric kettle auto shut-off mechanisms. It consists of two different metals bonded together, each expanding at a different rate when heated. When steam from boiling water reaches the strip, it causes it to bend and flex, which then triggers a mechanical switch to cut off power to the heating element, turning the kettle off.

How do I know if my kettle’s thermostat is broken?

If your kettle continues to boil indefinitely even after thorough descaling and cleaning of steam vents, and the physical switch seems to operate normally, it strongly suggests a broken internal thermostat or bimetallic strip. Other signs include the kettle consistently turning off too early or not heating at all. In these cases, the internal safety mechanism has failed.

When should I replace my electric kettle instead of fixing it?

You should consider replacing your Electric Kettle if basic descaling and cleaning don’t resolve the auto shut-off issue, if you suspect an electrical fault (burning smell, sparks), or if the kettle is old and has other performance issues. Often, the cost and safety implications of repairing internal components outweigh the cost of a new, safer appliance.